Experience the Future of Automation

In today’s fast paced world of manufacturing, more companies than ever before are turning to automation for some, if not all of their welding operations. An automated welding assistant could be just what your business needs to take it to the next level. Don’t be left behind!

Welding Automation Solutions

Welding automation is now crucial in order to compete with today’s leading competitors. You don’t want to be without it. The good news is that you don’t have to. Innovations in technology have created some of the most efficient, affordable, and reliable robotic welding assistants ever. There are many options available that will allow you to customize your automated program to make it a perfect solution for you.

We are committed to making your transition into the automation world as smooth as possible by offering live instructional demos and ongoing support!

Welcome to Automation.

Miller Co-Pilot Cobot

Advancing your skills doesn’t have to be complicated. Miller has made welding automation easier than ever with the all-new Miller Copilot Cobot. No complex software to slow you down, no barriers to training new operators and no reason not to evolve your workforce. The Copilot Collaborative Welding System’s welder-centric design responds the way a welder would want it to — without complex software or clunky controls to slow you down. Every welder can quickly and easily advance the way they work to strengthen your operation.

Ease of Use

Easy to learn and operate, Copilot Cobot removes complexity so that welders of all skill levels can be up and running within hours.

AccuGuide Precision Joystick

Our Copilot Cobot’s AccuGuide™ provides fingertip control for pinpoint torch positioning and perfect weld setting. Easy to learn. Easy to use.

IntelliSet Weld Settings Assistant

The most simple, intuitive interface and software empowers welders of any skill level to confidently produce repeatable, high-quality welds within minutes.

High-Mix, Low-Volume

Quickly and easily improve quality and increase throughput for high-mix, low-volume parts production to keep up with demand.

Large Work Table

- Robust 48″ x 48″ work table with 42″ x 30″ hole pattern.

- Up to 1,500-pound payload capacity

- Tooling hole pattern compatible with most modular fixturing

Power Supply

- Auto-Continuum™ 350 power supply with advanced welding capabilities

- Durable and reliable for everyday welding challenges

- Advanced capabilities like Accu-Pulse®, Versa-Pulse™ and RMD® processes to grow with your needs

Cooper Cobot Series

MADE TO MOVE.

Across many industries, finding skilled welders is challenging. In finding the best solution, automation is usually the most practical and cost-efficient answer. The Cooper Cart welding cobot is designed for safe, direct human interaction. It’s the affordable, game-changing solution you need to level up your welding and your business.

COOPER APP

Lincoln Electric created the Cooper App to make it simple for anyone to program and create a quality weld. On screen instructions guide users step-by-step through the process of creating welds, no training required.

- INCREASE PRODUCTIVITY & WELD QUALITY

Welds with an industrial ABB GoFa robot driven by a Lincoln Electric Power Wave® R450 power source. The Power Wave software controls and monitors welding processes delivering the highest levels of weld quality and productivity – exactly what you need to be more competitive. - RELIABILTY

Reduced maintenance and will not exceed the duty cycle of your equipment

Launch & Support

Our direct representative from Lincoln will ensure an easy and streamlined integration into your operation, helping with training and programming to get your transition to automation started off right.

Click the link below to schedule your Lincoln demo!!

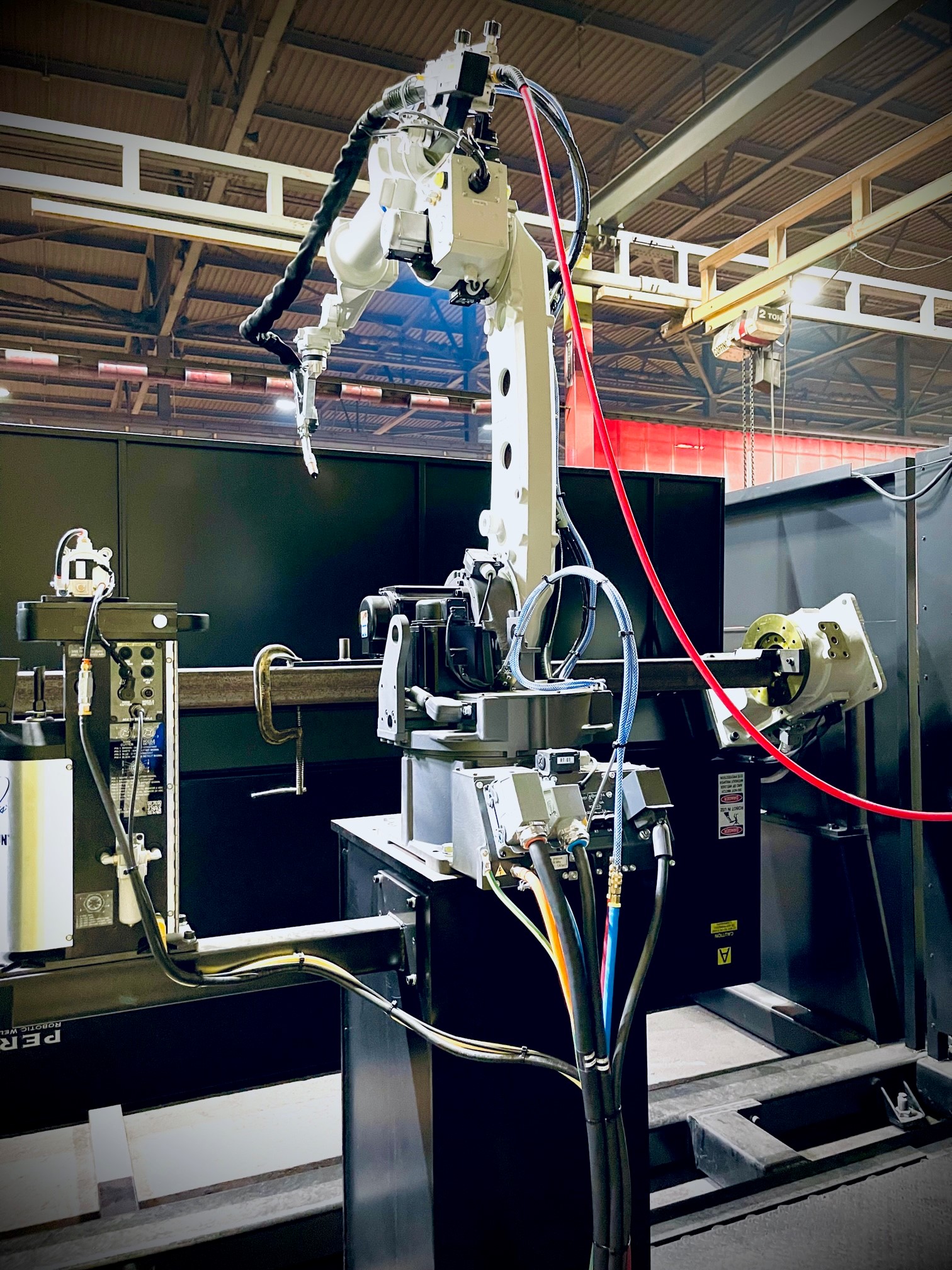

Robotic Welding Cells

PerformArc 1100FW

Extremely High Productivity

High speed “ferris wheel” positioner with three independent servo motors provides industry leading indexing times, which maximizes welding production time.

118″ span between the head and tail stock with 1100 lb. capacity on each side.

Available dual robot configuration allows a second robot to be added, theoretically doubling throughput with no additional floor space required.

GMAW and GTAW applications.

Load Station Flexibility

Optional load station jogging provides complete load position flexibility, allowing multi-stage loading or tack and finish welding to occur in a common welding fixture.

Servo Positioners allow the parts to be rotated into the desired welding position, maximizing torch access and welding quality.

Quick Assembly

A fully welded frame, pre-wired and pre-assembled ships in three sections for quick assembly.

Safety and Performance

Designed in accordance with ANSI/RIA R15.06-2012, UL1740, NFPA 79 and CSA Z434.

Long Term Support and Reliability

Setting the standard in the welding industry for quality, reliability and productivity since 1996. The PerformArc is backed by Miller today and tomorrow.

24/7/365 Support Line

Support Hotline provides customer service and parts support.

Full Range of Welding Processes

AccuPulse

AccuCurve

SP-MAG II

100% CO2

RMD

Active Wire Process -low energy short circuit and zero spatter.

GMAW-P

GTAW -with and without filler Aluminum -low pulse, dual pulse, synchronized weaving

Sevo Push-Pull Torch

Arc Data Monitoring

Offline Programming -DTPS

“Robots don’t get sick. They don’t get tired. Without automation, you’ll be left behind. And Welders Supply worked with us every step of the way to integrate our new system”

PerformArc 350S

High Production, Small Footprint

Small system fits in tight spots around the shop.

Extremely high output-to-investment ratio.

GMAW or GTAW applications

Extremely Fast AC Servo Turntable Positioner

Turntable rotates 180 degrees in under 2.2 seconds! Minimizing index

time and maximizing productivity.

Ships Fully Assembled

Completely pre-wired and pre-assembled, eliminates assembly time.

Easy to locate and connect the utilities.

Integrated Operator Control Panel

Control panel and full color teach pendant provide full system control, diagnostics and programming capability in one central location.

Safety and Performance

Designed in accordance with ANSI/RIA R15.06-2012, UL1740, NFPA 79 and CSA Z434.L-shaped light curtains, interlocked safety gates, dual channel safety circuit, rotating arc flash barrier and solid sheet metal wall panels.

Long Term Support and Reliability

Setting the standard in the welding industry for quality, reliability and productivity since 1996. The PerformArc is backed by Miller today and tomorrow

Full Range of Welding Processes

AccuPulse

AccuCurve

SP-MAG II

100% CO2

RMD

Active Wire Process -low energy short circuit and zero spatter.

GMAW-P

GTAW -with and without filler Aluminum -low pulse, dual pulse, synchronized weaving

Sevo Push-Pull Torch

Arc Data Monitoring

Offline Programming -DTPS